Ceiling fan size guide delmarfans com how to select the right for every room quick a ideas advice lamps plus is there an ideal your radle electric pin by mirko powell on fundamental of lighting large fans what do you need dan s city parts accessories selection mounting

Ceiling Fan Size Guide Delmarfans Com

How To Select The Right Size For Every Room

Ceiling Fan Size Guide Delmarfans Com

Quick Guide A Ceiling Fan Ideas Advice Lamps Plus

Ceiling Fan Size Guide Delmarfans Com

Is There An Ideal Size Fan For Your Room Radle Electric

Ceiling Fan Size Guide Delmarfans Com

Ceiling Fan Size Guide Delmarfans Com

Pin By Mirko Powell On Fundamental Of Lighting Ceiling Fan Size Large Fans

What Size Ceiling Fan Do You Need For Your Room Dan S City Fans Parts Accessories

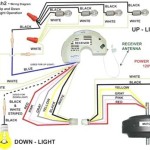

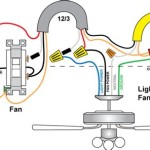

Ceiling Fan Selection Mounting Guide

How To Select The Right Size For Every Room

Ceiling Fans Sizing Guide How To Select The Perfect Size Fan For Your Space

Ceiling Fan Selector Indoor Universal Fans

Choose The Right Size Ceiling Fans For Your Room Smafan Com

Ac Motor Cooper Wire Winding Small Mini Size Kids Room Bedroom Department Use 15w Led Cct Light Ceiling Fan China And With

How To Size A Ceiling Fan 7 Steps With Pictures Wikihow

Ceiling Fan Guide The Home Depot

How To Choose A Ceiling Fan Size Style Hunter

Ceiling fan size guide delmarfans com how to select the right for every room quick a is there an ideal your pin by mirko powell on fundamental of what do you need selection mounting